製造流程

Production

球狀化處理之線材,依照鋼種不同(如碳鋼/硼鋼/合金鋼/工具鋼等),以及加工過程之不同,可分為熱軋球化材(SA ROD),伸線球化材(SAF),球化精抽材(SAIP),伸線軟化材(LAF),軟化精抽材(LAIP)等五類,每種類還可以依製造流程之不同再細分為若干類如下,必須依產品最終用途或功能(如汽車零件/工程用/手工具等)來選用不同製程。

Annealing wire can be divided into 5 different categories based on steel types (carbon steel, boron steel, alloy steel, tool steel…etc) and process types. The five categories are: SA Rod, SAF, SAIP, LAF, and LAIP; listed below are their specific pathways.

球化處理是什麼?

What is spheroidizing Annealing?

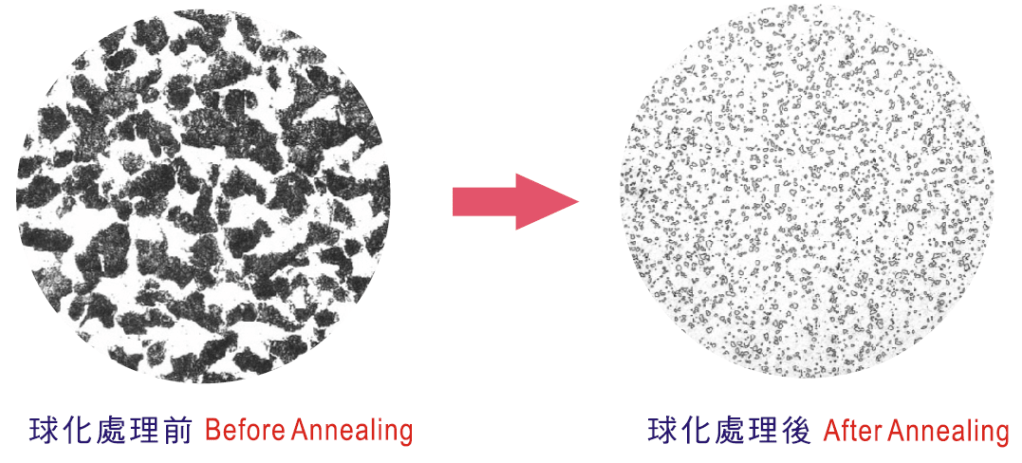

球狀化處裡主要是將鋼材加熱到變態點以上,再配合一系列降溫及升溫的過程,將鋼材中的碳元素顆粒變小,均勻分布在肥力鐵結構內,經過球狀化處理後的鋼材有更佳的延展性及塑性,可用來冷鍛加工較複雜與高附加價值的產品,在扣件及手工具產業的轉型升級中,高品質的合金鋼球化材是不可缺貨的原料,而日本大同STC爐則是生產高品質球化材最具口碑的世界級廠商,目前已有一套設備,計畫在2023年會再增設第二套設備。

The purpose of the annealing process is to refine the grain size and improve the ductility. The process includes a series of heating to critical temperatures and cooling; Thereafter the grain size of carbon will become fine and uniform in the Ferrite structure. The annealed alloy steel is necessary for the manufacturing of high end fasteners and auto parts. The Japanese Daido STC annealing furnace has gained its reputation as having the highest quality in this field. We installed one set of STC furnace in 2017 and will install the second set in 2023.

什麼鋼種會需要球化處裡?

What kinds of steel would benefit from spheroidizing annealing?

低碳鋼 Low Carbon Steel

1001, 1006, 1008, 1015, 1018, 1022

中碳鋼 Medium Carbon Steel

10B21, 10B33, 10B38, 1035, 1040, 1045, 35ACR, 40ACR

合金鋼 Alloy Steel

SCM415, SCM420, SCM435, SCM440, 4037, 4140, SCR435, SCR440, SNCM439

工具鋼 Tool Steel

50BV30, 6130, 6140, 6150, 60SCRV, SUJ2, S2, S55C, 8660V, SNCM439